Composite Materials: Lightweight, Strong, and Full of Potential

- dsarikamis

- Jan 4

- 4 min read

They are lightweight, extremely strong, and indispensable in many high-tech applications: composite materials. Thanks to their tailor-made properties, they open up new possibilities in design and engineering. At the same time, they require a deep understanding of material behaviour, manufacturing processes, and simulation. We show what makes composite materials unique, where their limitations lie, and how companies can harness their full potential in a targeted way.

What are composite materials?

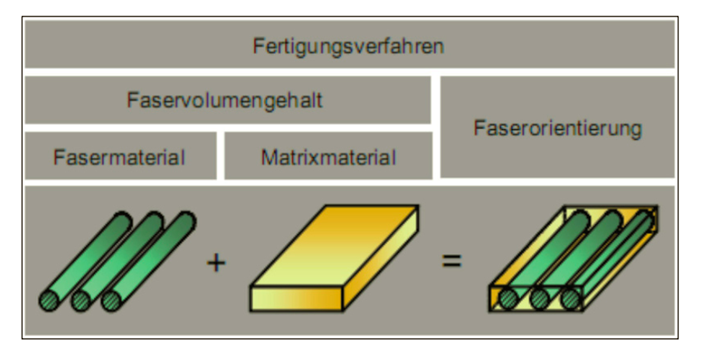

Composite materials are materials made by combining different components. An important subgroup is fibre-reinforced composites (FRC), also known as fibre-reinforced plastics or simply composites.

The key advantage of composite materials lies in their ability to be tailor-made for specific applications. By carefully selecting the components and appropriate manufacturing processes, their properties can be precisely adapted, making them attractive for a wide range of applications.

Fibre-reinforced composites are characterised by fibres that reinforce the polymer matrix – similar to how wood fibres strengthen trees – significantly improving mechanical properties. The interaction between the fibres and the polymer matrix is crucial:

Fibres alone can withstand high tensile loads but are unsuitable for components subjected to bending or compressive loads.

Unreinforced plastics can form components, but are often either too brittle or too flexible.

Only the combination of fibres and polymer, together with strong bonding between the matrix and the fibres, enables the production of highly load-bearing components. Typical examples include aircraft and automotive components as well as sports equipment such as skis.

Reinforcement fibres today consist mainly of glass fibres, carbon fibres, aramid fibres, and natural fibres. These fibres are characterised by their low density and provide the reinforced polymers with high strength and stiffness.

Below is an example illustrating how the Airbus A380 was developed using different composite materials, each tailored to specific load cases.

Market for Fibre-Reinforced Composites

Over the past five decades, global plastics production has grown steadily – by an average of almost 10% per year. Currently, around one quarter of global plastics production takes place in Europe. Within Europe, Germany is the largest producer, accounting for approximately one third of this volume.

The market for fibre-reinforced composites represents a relatively small but highly significant segment of the plastics industry due to its unique properties. Although production volumes account for less than 5% of total plastics production in Europe, applications are often highly innovative and technologically demanding – for example in aerospace, automotive engineering, and renewable energy.

Advantages and Applications of Fibre-Reinforced Composites

Compared to conventional materials, composite materials offer numerous advantages and are therefore becoming increasingly popular across many industries. The most important advantage is their exceptional strength-to-weight ratio. They combine low weight with high strength and stiffness, making them ideal for applications where weight reduction is critical, such as aerospace, automotive engineering, and sports equipment.

The low weight of composite materials not only improves fuel efficiency, but also enables faster acceleration, better manoeuvrability, and reduced structural fatigue.

Another key advantage is their excellent corrosion resistance. Unlike metals, which can corrode or degrade when exposed to moisture, chemicals, or harsh environments, composite materials are highly resistant. This makes them ideal for applications in maritime environments, the chemical industry, and infrastructure, where durability and long-term performance are essential.

By using composite materials, companies can reduce maintenance costs, extend the service life of structures, and ensure consistent performance even under challenging conditions.

In addition, composite materials offer a high degree of flexibility and versatility in design. By varying fibre types, fibre orientation, volume fractions, and by selecting appropriate resins and additives, mechanical, thermal, electrical, and acoustic properties can be precisely tailored. This enables the development of customised solutions for a wide range of applications.

The ability to create complex shapes, intricate geometries, and integrated functions further expands design possibilities and opens up new opportunities in industries such as architecture, consumer goods, and renewable energy.

These characteristics make composite materials highly attractive for a wide range of applications, as they offer improved performance, durability, and efficiency compared to conventional materials.

Disadvantages and Limitations

Despite their many advantages, composite materials also have certain limitations that must be considered when selecting and applying them.

One of the greatest challenges is the high manufacturing cost. Production requires complex processes and expensive raw materials such as carbon fibres, making composites less economical for many applications.

In addition to high costs, the mechanical behaviour of composite materials presents further challenges. Composites are brittle and do not exhibit ductile failure like metals – damage often occurs suddenly and without prior warning. Furthermore, their pronounced anisotropy means that strength and stiffness are primarily effective along the fibre directions, making material properties highly direction-dependent.

As a result, design and engineering require a high level of expertise. Errors in fibre orientation or laminate design can significantly reduce strength and lead to premature failure.

Opportunities for Composite Materials with cross-ING

To overcome these challenges, specialised expertise is essential. This is exactly where we come in. With our experienced engineering team and extensive expertise in material design, manufacturing technologies, and simulation, cross-ING supports your company in using composite materials to their full potential.

Through tailored solutions and sound engineering consultancy, cross-ING creates a clear competitive advantage – from the concept phase through to series production. This enables you not only to benefit from the advantages of advanced composite materials, but also to ensure the quality, safety, and economic viability of your products.

Would you like to explore this topic in more depth?

Book an expert consultation now and receive tailored advice from our specialists.

Want to learn more about our Competence Center MATERIALS at cross-ING?

Discover how our interdisciplinary team tackles complex technical challenges.

Comments